Plastic cutting pellet machine

A plastic cutting pellet machine, also known as a plastic pelletizer or granulator, is a specialized machine used to process plastic materials into small, uniform pellets or granules. These pellets are easier to handle, transport, and use in subsequent manufacturing processes. Here’s how it works and its key components:

How It Works:

Feeding: Plastic waste or extruded plastic material is fed into the machine. This can come from various sources, such as post-consumer waste, production off-cuts, or extrusion lines.

Cutting: The core function of the machine is to cut the plastic material into small, consistent pellets. This is achieved using a set of rotating blades or knives that chop the plastic into the desired size.

Cooling: After cutting, the plastic pellets need to be cooled to solidify them and maintain their shape. This is typically done using a water bath or air cooling system.

Drying: Depending on the type of plastic and the process, the pellets may need to be dried to remove any residual moisture.

Collection: The finished pellets are collected in a container or bag for further use. They can be used as raw material for manufacturing new plastic products or for further processing.

Plastic cutting pellet machine

Key Components:

- Feeding System: This may include hoppers or conveyors that transport the plastic material into the cutting area.

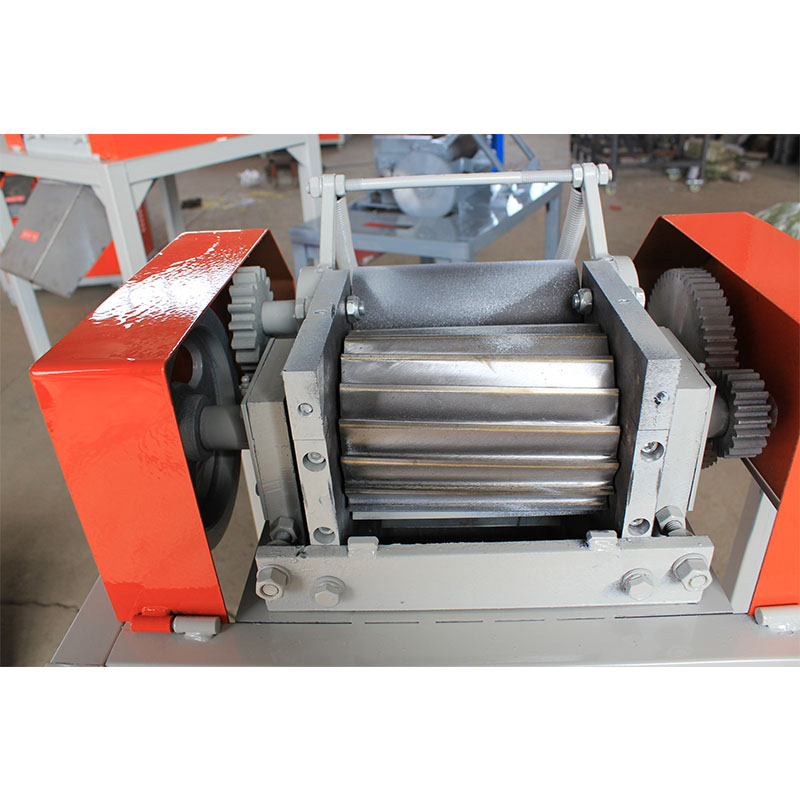

- Cutting Blades: These are sharp, rotating blades that chop the plastic into pellets. The design and arrangement of the blades can affect the pellet size and shape.

- Cooling System: Often a water bath or air cooling system that solidifies the pellets after cutting.

- Control System: Manages the operation of the machine, including feed rate, cutting speed, and other parameters.

- Screen or Filter: Ensures that only pellets of the desired size are collected, with excess material being recirculated or discarded.

Plastic cutting pellet machine

A plastic cutting pellet machine, or pelletizer, processes plastic into small, uniform pellets. It works by feeding plastic waste or extrusions into the machine, where rotating blades cut it into pellets. The pellets are then cooled, dried if necessary, and collected for reuse in manufacturing or recycling. This machine helps make plastic materials easier to handle and process.